Much like a builder must choose the right materials to construct a safe and durable house, food manufacturers have to choose the right ingredients to create high quality, consistent products.

One wrong choice can make even the most impressive concept fall flat. Alliums are particularly volatile, especially when used in their fresh or dry powder forms. Here are a just few of the challenges they present, and how extracts can help save the day.

Challenge No. 1

“Natural variation occurs from crop to crop causing inconsistencies in my final product at shelf.”

Like any other crops, the flavor of alliums can change based on uncontrollable factors, such as soil quality, weather patterns and other growing conditions. Even if those conditions are controlled, fresh alliums can fluctuate in flavor as a result of transportation and warehousing. In fact, handling and storage of onion bulbs for 5-6 months can result in loss of fresh notes by about 25 to 30%. Extracts eliminate these fluctuations because their flavors are standardized, eliminating concerns over crop-to-crop variations, transportation conditions and storage timelines.

Challenge No. 2

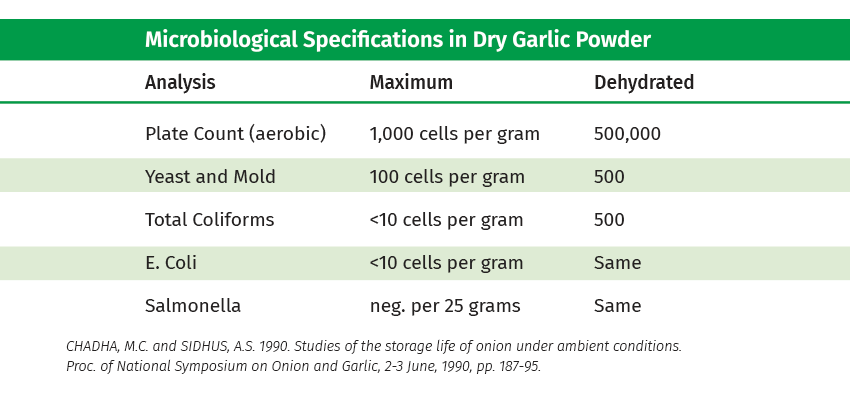

“Dry spices are well known for their high microbiological levels!”

The microbiological content of garlic powder is higher than garlic extract by as much as 500 times, leading to investments in manpower and counter solutions that keep the microorganisms in control. By replacing powder with extracts, you can flatten the number of unfavorable variables during the production process, making it more efficient—both in production time and overall cost.

Challenge No. 3a

“I’m always being asked to reduce the cost of my ingredients.”

Because extracts are so highly concentrated, they provide a significant cost savings to the overall formula cost, ranging from 1:10 to 1:40 compared to dry alliums.

Challenge No. 3b

“I like the sound of cost savings, but my customer expects to see pieces of garlic/onion in my product”

In these cases, a partial replacement can still provide significant cost savings while maintaining the right appearance and ingredient declaration. It’s a win/win/win.

source: https://foodprint.org/real-food/leeks/

Challenge No. 4

“Storage, handling and transportation of dehydrated alliums can be complex and with the current pandemic, logistics continue to be a challenge.”

Because of their stability, extracts have a long shelf life and do not require refrigeration. Additionally, due to the extracts being heavily concentrated, you reduce both your warehouse space needs and have reduced volumes during shipping.

While these challenges are significant, it is by no means a comprehensive list. The advantages allium extracts provide to product formulations provide many answers to ongoing challenges faced by product developers. The Kalsec team of chefs and food scientists make sure your solution is strong with high-quality, natural extracts that deliver improved shelf life, consistency and efficiency while meeting consumer demand for cleaner labels and uncompromising taste.

Dry Spice Replacement Using Kalsec Extracts

Watch a Kalsec expert explain how to easily replace dry spices with extracts from Kalsec.

Watch Video